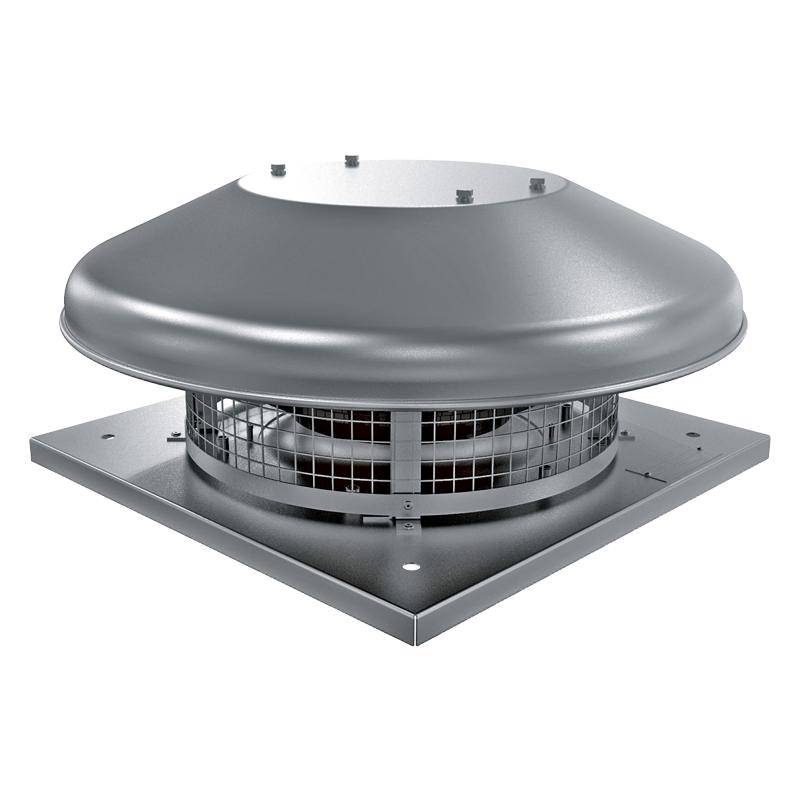

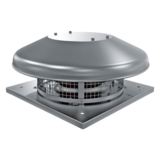

Blauberg Tower-HC EC 190

EAN4058448103018

EAN4058448103018 - Description

- Characteristics

- Downloads

- Dimensions

- Additional characteristics

- Designation key

- Accessories

| USE | |

|

Extract ventilation systems installed in various premises.Roof mounting.Any roof types.For arranging energy-saving and controllable ventilation systems. |

|

| DESIGN | MOTOR |

|

The casing is made of steel with a polymer atmospheric resistant coating.Horizontal air exhaust.The fan is equipped with a terminal box for connection to power mains.The fan is rated for continuous operation always connected to power mains.The impeller has a protecting grille.The upper cover is equipped with two eye bolts for easy fan lifting on the roof with hoisting mechanism.A connecting plate is provided to facilitate mounting to the roof surface or to the mounting frame. |

High-efficient direct current EC motor with external rotor and backward curved blades.EC technology meets the up-to-date requirements to energy-saving and controllable ventilation and provides up to 35 % energy saving as compared to asynchronous motors.EC motor ensures totally controllable speed range for the fan and has integrated overheating protection with automatic restart.EC motor has no friction and wearing parts as capacitor und brushes. Instead a maintenance-free EC controller electronic circuit board is used.The impeller is dynamically balanced.The fan is compatible with 50 Hz and 60 Hz power mains and the maximum speed does not depend on power mains frequency. |

| OPERATION AND SPEED CONTROL | MOUNTING |

|

The fan speed is controlled with a 0–10 V control signal from the following sources:

The control signal value changes depending on air temperature, pressure, smoke concentration and other parameters.During signal value change the fan with EC motor correspondingly changes the rotations speed and delivers required air volume to the ventilation system.The computer central building management systems (BMS) enable integration of several EC motors in network and precise individual operation control for each fan. |

Roof mounting directly above a ventilation shaft or an air duct.The fan is attached to a square air duct or to the MRDL/MRIDL mounting frame (see accessories).The counterflange FDL mounted on the fan bottom (see accessories) is designed for the fan connection to a round air duct.The KDL backdraft dampers (see Accessories) are designed to prevent air back drafting when the fan is off.The VDL flexible connectors (see Accessories) are designed to absorb vibration from the fan to the air duct.External terminal box for connection to power mains. |

Domestic fans

Domestic fans Industrial fans

Industrial fans Single-room air handling units with heat recovery

Single-room air handling units with heat recovery Air handling units

Air handling units  Smoke extraction and ventilation

Smoke extraction and ventilation Ventilation accessories

Ventilation accessories Ventilation ducts and fittings

Ventilation ducts and fittings Air distribution

Air distribution Measurement and control technology

Measurement and control technology Ventilation sets and vents

Ventilation sets and vents