Blauberg BSK2

- Description

- Downloads

|

|

|

||

|

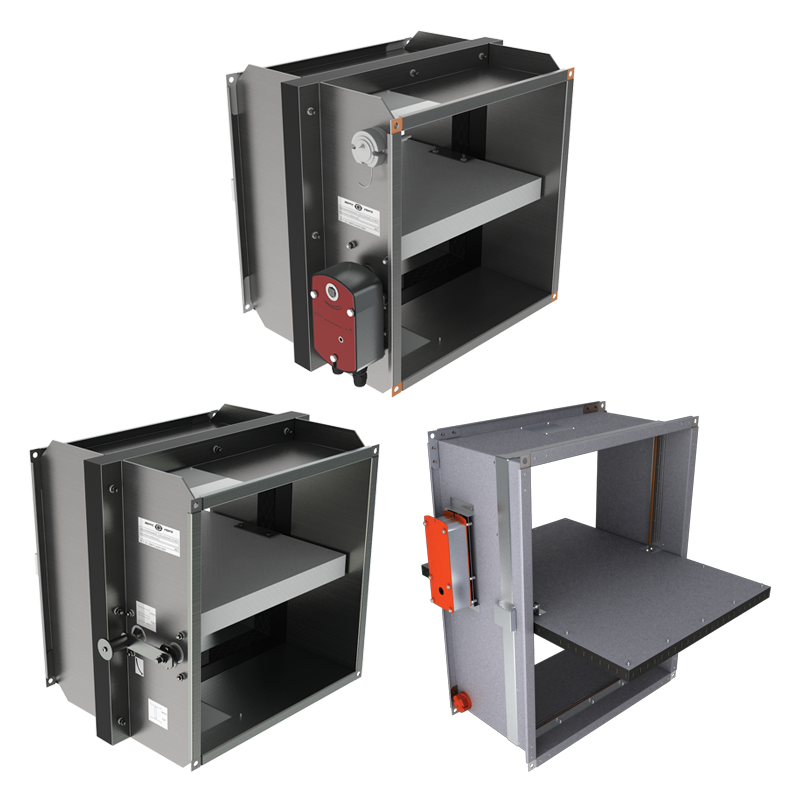

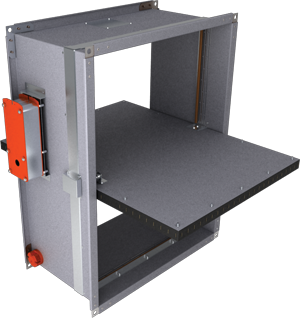

BSK2...72S normally open fire-resisting duct damper with a mechanical drive mechanism |

BSK2...PKPBSK2...PVPBSK2...PSPnormally open fire-resisting duct damper with electric drive mechanism |

BSK2...PKP...SBSK2...PVP...SBSK2...PSP...Snormally open fire-resisting duct damper with a simplified design with an electric drive mechanism |

| USE

The fire-resisting dampers are intended for automatic closing of process openings and air duct penetrations in intermediate floors, walls and partitions, as well as closing of openings in supply and exhaust ducts of smoke ventilation systems. The dampers of this particular design are not suitable for installation in air ducts and ducts of premises with rated explosion and fire safety category A and B and in flammable and explosive mixture intakes. The BSK2 fire-resisting duct dampers are capable of resisting fire for at least 120 minutes (EI 120) at the temperature of 600 °C. |

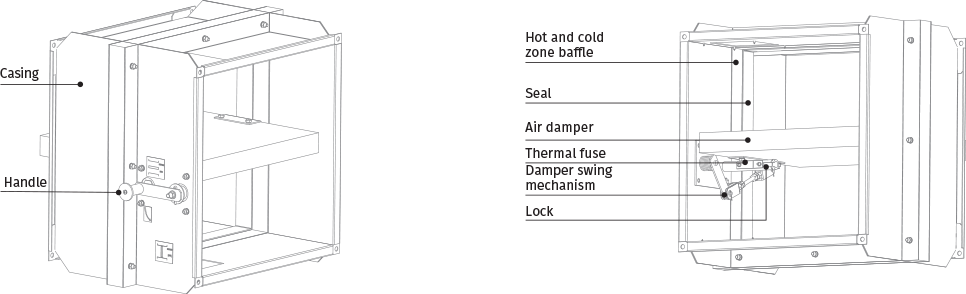

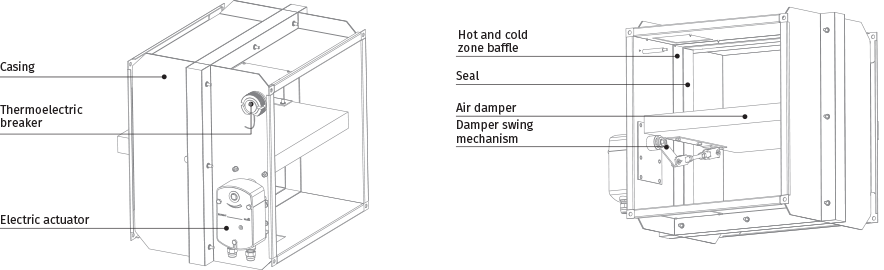

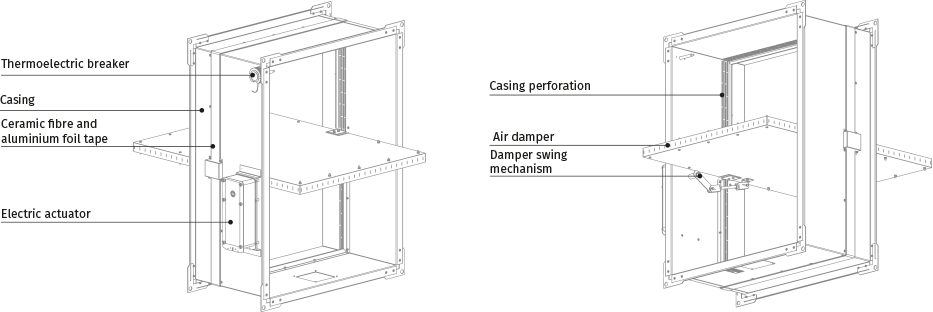

DESIGN

The BSK2 series dampers are made in the general-purpose industrial version with a minimized variety of hardware components using low-alloy galvanized steel. The damper flap is made of fire-resistant material. The duct installation design results in two mounting flanges on the casing for integration into a ventilation ducts (air ducting) and external configuration of the drive mechanism for easier maintenance. The BSK2...PKP/ BSK2...PVP/ BSK2...PSP dampers are equipped with a hot and cold zone baffle. The BSK2...PKP...S/ BSK2...PVP...S/ BSK2...PSP...S dampers have a simplified construction:

|

|

| CONTROL AND MODIFICATIONS

Depending on the design variant the BSK2 series dampers are equipped with: |

||

|

MECHANICAL ACTUATING UNIT WITH A THERMAL FUSE AND A RETURN SPRING The damper is set to the operating position upon the thermal fuse breakdown resulting from a temperature increase. The damper can then be re-set to the protective position only manually by using a handle and by replacing the thermal fuse through the access hole. Emergency damper actuation: the flap remains in protective position (damper unaffected by fire) and is fixed by a thermal fuse (when the flap is installed in security position, a reverse spring is activated). Upon emergency actuation (damper directly affected by fire) the thermal fuse breaks down and the return spring moves the flap to operating position. |

ELECTRIC ACTUATOR WITH A BUILT-IN RETURN SPRING AND A BACK-UP THERMAL BREAKER Setting the damper to operating position (direct fire contact): remotely, via electric actuator. The damper can be set to the operating or protective position either remotely via the control panel or manually using the manual cocking handle which is always included in the standard delivery set of the electric actuator. In case of the remote control panel failure, the back-up thermal breaker interrupts the power supply to the electric actuator and the return spring sets the damper to the operating position. Emergency damper actuation: The damper flap is set to the protective position automatically (damper unaffected by fire). The electric actuator remains energized at all times.In case of an emergency actuation (direct fire contact), the electric actuator equipped with a return spring is de-energized and the damper flap is set to the operating position by means of the spring energy. In case of a power failure not related to fire and its subsequent restoration at the actuator with a return spring, the damper flap returns to protective position. |

|

| THE BSK2...72S FIRE SAFETY DAMPER WITH A MECHANICAL ACTUATING UNIT WITH A THERMAL FUSE AND A RETURN SPRING

|

||

Domestic fans

Domestic fans Industrial fans

Industrial fans Single-room air handling units with heat recovery

Single-room air handling units with heat recovery Air handling units

Air handling units  Smoke extraction and ventilation

Smoke extraction and ventilation Ventilation accessories

Ventilation accessories Ventilation ducts and fittings

Ventilation ducts and fittings Air distribution

Air distribution Measurement and control technology

Measurement and control technology Ventilation sets and vents

Ventilation sets and vents