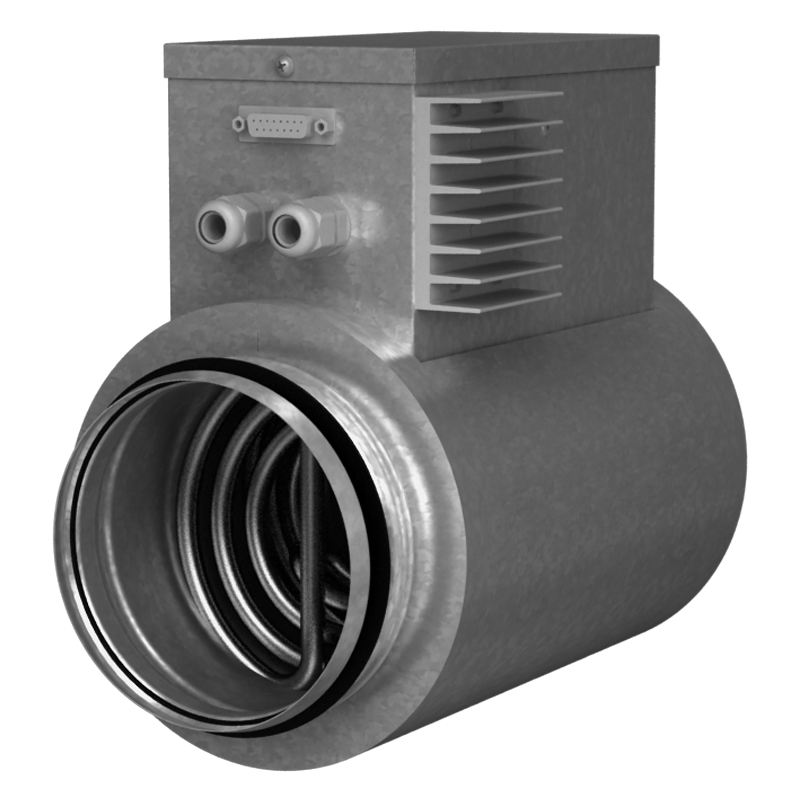

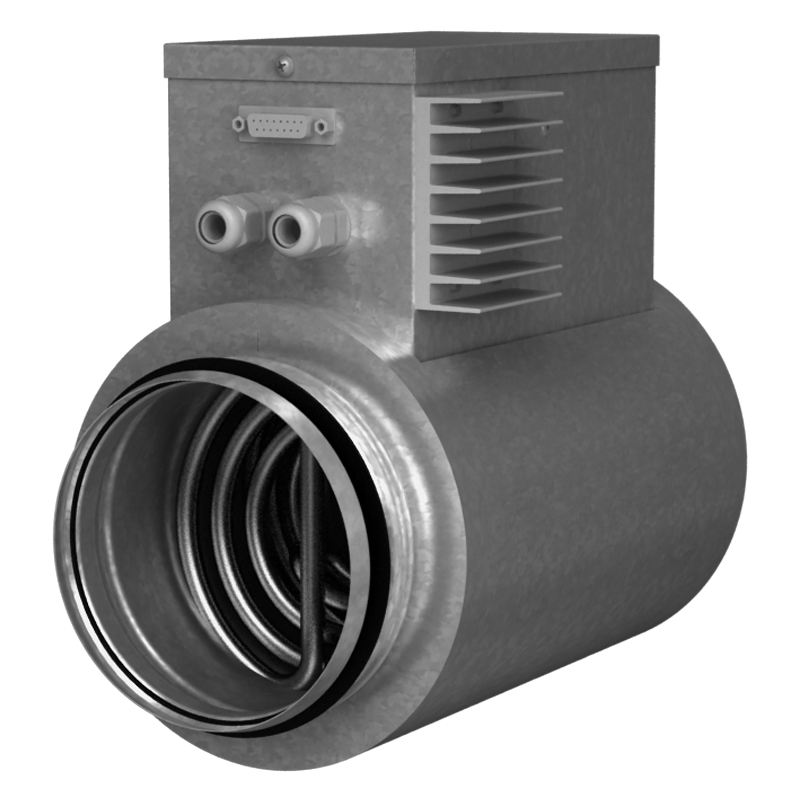

Blauberg ENH (round)

- Description

- Modifications

- Downloads

- Designation key

- Compatibility chart

- Heater capacity selection diagram

| FEATURES

The heater is designed for integration into a ventilation system and joint operation with an air handling unit equipped with a control system used to switch on the heater and control its operation. The heater maintains the supply duct air temperature at a point set by the unit controller.Compatible with Ø 125 up to 250 mm air ducts. MOUNTINGThe heater design ensures its mounting on the round ducts in any position by means of clamps (included in delivery). The air flow direction shall match the direction of the arrow on the heater casing.In case of horizontal mounting the control box must be installed with the cover upwards. Swivel range from the normal position up to max. 90°. Do not install the control box with the cover downwards. |

DESIGN

The casing, the junction box and the heater cover are made of galvanized steel with the heating elements in stainless steel. The heater casing is additionally heat-insulated with 20 mm non-flammable mineral wool layer. The heaters are equipped with rubber seals for airtight connection to the air ducts. The ENH duct heaters are equipped with a power and a signal cable for connection of the heater to the air handling unit controller. The temperature is controlled by a triac power controller by means of switching the full load on and off. Load commutation is carried out by the semiconductor device (triac). The heaters are equipped with overheat thermostats:

|

| Modification name | |

|---|---|

| ENH 125-0.6-1 S21 | |

| ENH 125-0.8-1 S21 | |

| ENH 125-1.2-1 S21 | |

| ENH 150-0.8-1 S21 | |

| ENH 150-1.2-1 S21 | |

| ENH 150-1.7-1 S21 | |

| ENH 150-2.0-1 S21 | |

| ENH 160-0.8-1 S21 | |

| ENH 160-1.2-1 S21 | |

| ENH 160-1.7-1 S21 | |

| ENH 160-2.0-1 S21 | |

| ENH 200-1.2-1 S21 | |

| ENH 200-1.7-1 S21 | |

| ENH 200-2.0-1 S21 | |

| ENH 250-1.2-1 S21 | |

| ENH 250-2.0-1 S21 | |

| ENH 250-3.0-1 S21 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Series | Connected air duct diameter [mm] | Heater power [kW] | Number of phases | Compatibility with automation | ||

| ENH | 125; 150; 160; 200; 250 | – | 0.6; 0.8; 1.2; 1.7; 2.0; 3.0 | – | 1: single-phase | S21: compatible with S21 automation |

| Heater model | Unit model |

| ENH 125 ... S21 | KOMFORT with spigot Ø 125 mm and S21 control panel |

| ENH 150 ... S21 | KOMFORT with spigot Ø 150 mm and S21 control panel |

| ENH 160 ... S21 | KOMFORT with spigot Ø 160 mm and S21 control panel |

| ENH 200 ... S21 | KOMFORT with spigot Ø 200 mm and S21 control panel |

| ENH 250 ... S21 | KOMFORT with spigot Ø 250 mm and S21 control panel |

/ENH-selection-diagram-500-EN-2020.png) |

The ENH heater parameters calculation example: It is necessary to select a heater for supply air post-heating to a temperature of +24 °C, provided the temperature downstream of the heat exchanger is +17 °C. Therefore it is essential to increase temperature by +7 °C. The ventilation system incorporates the KOMFORT EC SB 350 S21. Rated air capacity 400 m³/h.Determine the intersection of the post-heating temperature line (+7 °C) and the rated air capacity line (400 m³/h). In this case the 1200 W heater capacity provides necessary post-heating (+7 °C). The ENH 160-1.2-1 with the diameter matching the spigot diameter of the air handling unit KOMFORT EC SB 350 S21 is a suitable model. |

Domestic fans

Domestic fans Industrial fans

Industrial fans Single-room air handling units with heat recovery

Single-room air handling units with heat recovery Air handling units

Air handling units  Smoke extraction and ventilation

Smoke extraction and ventilation Ventilation accessories

Ventilation accessories Ventilation ducts and fittings

Ventilation ducts and fittings Air distribution

Air distribution Measurement and control technology

Measurement and control technology Ventilation sets and vents

Ventilation sets and vents